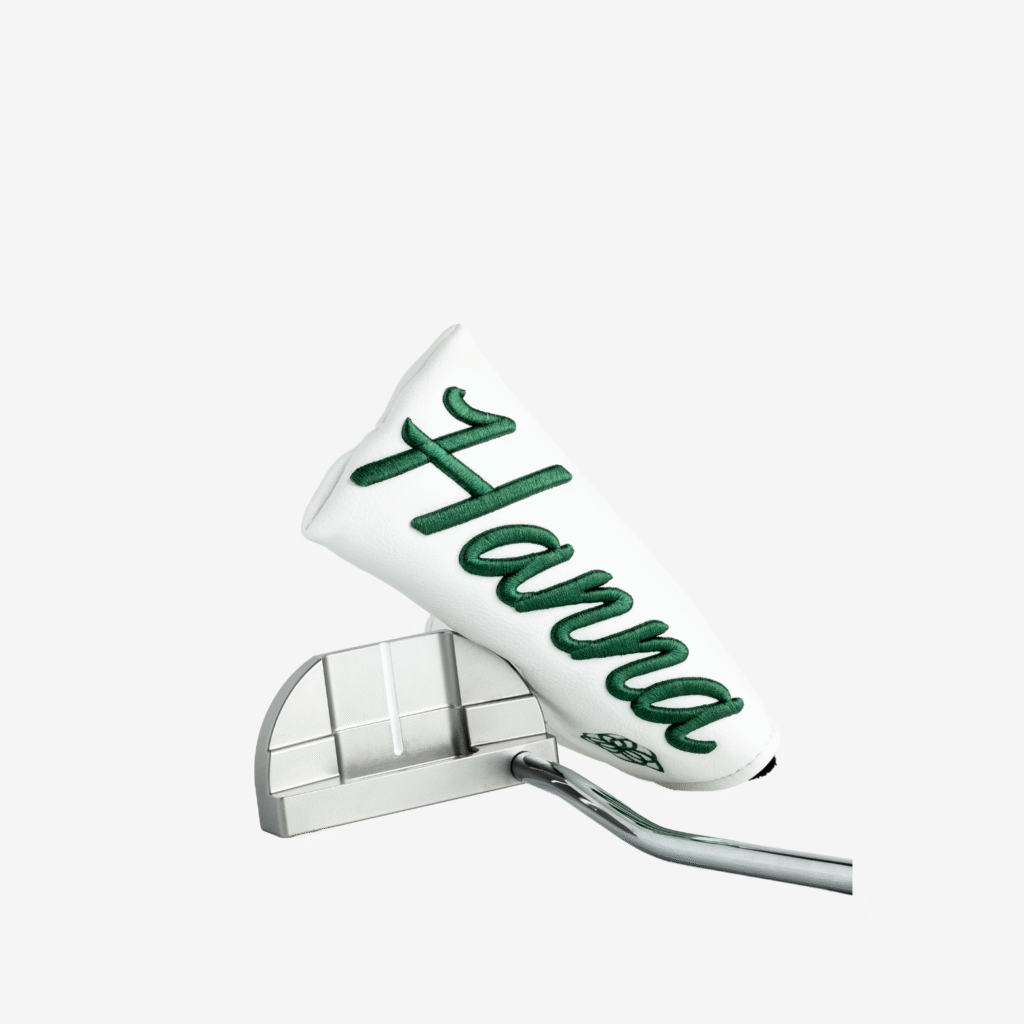

Hanna Golf is a boutique putter company that designs, CNC mills and assembles all their putters in Iowa. Jared Doerfler, a former collegiate golfer at the University of Northern Iowa, founded the company just over a year ago.

Fairway to Green’s Nathan Rarick had the opportunity to talk with Doerfler for the first segment of our fall putter series.

Nathan Rarick: What inspired you to found this company?

Jared Doerfler: Two reasons: When I arrived at the University of Northern Iowa, my golf coach put me on our putting software. I was using a traditional blade putter with a plumber’s neck. It took all of two strokes for my coach to go to his closet and pull out a different putter for me. It was a prototype blade putter with an original SuperStroke grip (this was in 2008). He picked the putter up off a tour truck in the late 90s at a PGA Championship.

The putter didn’t feel great and didn’t sound great, but I made everything with it. After I graduated, I gave it back to Coach Bermel. Once a year, I’d find myself on eBay trying to find that putter to buy. I could never find it. I had bought other CNC milled mallets, but it just didn’t feel right. So a decade after I graduated, I drew what I thought that putter looked like on a piece of paper, had my brother-in-law draw it in CAD (Computer-aided Design) and had a buddy at a machine shop in Texas mill it for me. It turned out terrible, looked terrible and was too heavy, but I thoroughly enjoyed that project. It was so much fun.

My dad was diagnosed with MS in 2012. He retired a couple of years ago, and when he told me he was retiring, it hit me. Life goes by far too fast, faster than we think. And now that he is retired, he can’t enjoy the things he’d like to do in retirement due to the disease. He can’t play golf, ride his bike, snow ski, etc. We never know when we will have a life-altering event. And what is failure really? I had been itching to do something, to make something, to build something. And I loved the golf putter project – so we went all in on that.

NR: How hard was it to learn how to mill putters?

JD: Hardest thing I have ever done in my professional career and it isn’t close. You have to be naive to think you can pull it off. There are really three components that go into milling putters. CAD, CAM (Computer-aided Manufacturing) and running CNC Mills. CAD wasn’t overly difficult to learn, and there is a ton of support online. And it is sort of black or white, did you create the 3D model that you wanted or not? CAM, on the other hand, has been extremely complex. I still learn something new every week. CAM is the software that generates your toolpaths and G Code for the mills. You don’t just push a button on CAM and say give me my toolpath. It is all about the inputs you provide. And teaching myself how to run CNC mills is still something I look back on and say I am shocked I have taught myself as much as I have. It has been incredibly rewarding.

NR: Can you describe your process of creating a putter?

JD: Each putter starts as a 72-inch 303 Stainless 2×4 that gets cut down to 4 inches in length with a band saw. After that, we prep the billets with a facing operation to ensure quality and consistency. Each putter has four operations since we have three axis CNC mills. In the first operation, we run six putters at once and do a lot of the work that goes into milling a putter. The second operation is milling the bore hole and sightline. In the third operation, we do some blending toolpaths and engraving on the bottom. And the fourth operation is when the putter gets finished. We take off the stock, mill the loft, mill the face pattern and do some more blending.

After putters come off the mill, they hit the belt and some Scotch-Brite along with getting bead-blasted and cleaned. Then they are painted, shafted, cut and gripped and sent out the door.

NR: What are your future plans and goals for Hanna Golf?

JD: Since I emptied my bank account to self fund this business, I am quite frankly just trying to get to each month. We aren’t as strategic as I’d like right now, and I think that is relatively common in a new business – we’ve been at it for a little over a year. Of course, I’d like us to come out with new designs, add more machines and continue to grow. But to do that, we need to win each day and week. We are just focused on the process and seeing where the results will take us.

NR: What makes your putter different from the big-name companies?

JD: We have a few product differentiators. We actually mill our own putters, and we mill them in America. Some companies outsource design, some outsource design and manufacturing, and some outsource manufacturing to other countries. Some outsource manufacturing to job shops in America. But there aren’t many golf companies that are manufacturing their own product themselves.

NR: What are your customization options for your putters?

JD: Things we advertise on our website are length, grip, finish and initials engraved. But we get emails weekly from customers that want to do something different with their putter, whether that is finish, lie angle, logo on the bottom, etc. If we can do it, we will.

NR: Do you have any professional golfers or golf influencers using your putter?

JD: We have a golfer on the PGA Tour that has one of our putters. The cool thing about it was it was organic. He bought it off the site last fall. I thought we were close to having him put it in the bag, but it didn’t happen. I was at a tour event earlier this summer, and we just aren’t ready or prepared to serve most of these golfers. They can walk in a tour truck and get a modification in an hour. Looking inwardly – we aren’t there. But we aspire to get there. We have some high-level amateurs and mini tour guys with our putters. I am really excited where we are at in terms of the caliber of golfer using our putters.